Processing the production program

The production program comprises one or several end or intermediate products which are to be produced in a certain quantity in a Layout Area (the layout) within a specified reference period (planning period: 1 year). Similar products are summarized in Product Families to reduce the complexity.

visTABLE®logix describes a production program in the View of the Production Program by way of overviews of

- Product families with their Product Flows, i.e. the main flows,

- Types of Transport Means with Cost Structure,

- Containers or types of transport aids where necessary and

- Parts and materials in the auxiliary flow where necessary.

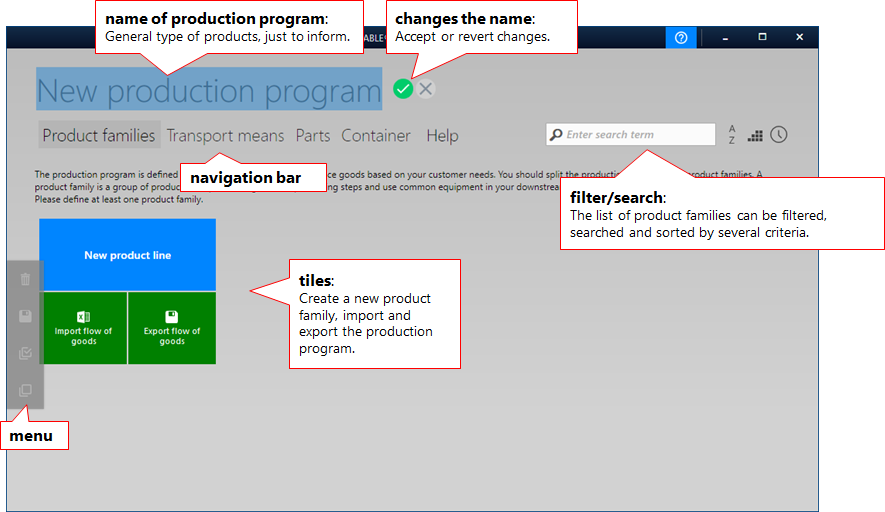

Overview of product families

The View of the Production Program starts with an overview of the product families. The following tasks can be started from here:

- Creation of a new product family;

- Deletion of one or several product families,

- Copying of a product family within the production program,

- Filtering and sorting of the thumbnails in the overview,

- Export or import of product flows.

Actions for product families

Product families can be created, copied or deleted.

- To create a product family, use the

New Product Familybutton. A new product flow chart with 2 process boxes results. Is recommended to assign the product family a name and the automatically created process boxes appropriate identifiers immediately after their creation. - To copy a product family, use the

Copy Symboldirectly beneath the thumbnail. A name and a quantity must be specified for the copy; all the other data are inherited from the original. The numbers of transports are referred to the newly entered annual quantity. - To delete a product family, use the

Recycle Bin Symboldirectly beneath the thumbnail. Deletion must be explicitly confirmed. It cannot be undone.

Color coding

The color is used to visualize the flow in the layout in 2D and 3D. It is therefore recommended to assign each product family its own color.

Combined actions for several product families

If several product families are specified in the View of the Production Program, they can be sorted and filtered by different criteria and selected or deleted either separately or as a selection:

- A thumbnail is provided for each product family which displays its structure (the product flow).

- The designation of the product family and the annual quantity are specified under the thumbnail. If the date of last change is activated as the sorting criteria, the date of the change is also displayed.

- Product families can be selected e.g. for deletion by way of the checkbox in the top right corner of the thumbnail.

- The designation of the product family and the annual quantity are specified under the thumbnail. If the date of last change is activated as the sorting criteria, the date of the change is also displayed.

- The sorting options in the

Product Family Filtercan be used to sort the product families in ascending or descending order by

- Name,

- Annual quantity or

- Date of last change.

- Name,

- The filter itself reduces the view of the preview images, regardless of any previously made selection (activated checkboxes), to those product families that contain the entered text either

- in the name of the product family or

- in the name of an assigned resource.

- in the name of the product family or

- The menu provides the following actions, depending on the selection:

Select allproduct families of the filtered selection.Discard selection; no product family is selected.Deletethe selected product families from the production program.Exportthe selected product families to xlsx.

Thumbnails

The thumbnails can be empty, e.g. after importing product flows, since a thumbnail is only generated when the product family is opened for the first time. In this case, the thumbnail is gray; it nevertheless comprises data.

Importing and exporting product flows

Product flows are imported and exported by converting the product flow charts and the contained process information from or into Excel tables.

Structure of the product flows

A logical structure can be represented by way of various charts. Both the export and the import take into account exclusively the logical structure. In other words: The graphical representation after importing an exported product can under certain circumstances be different.

Access to the import and export functions in visTABLE®logix is provided from the View of the Production Program. Like all the other actions for data exchange, these two actions for movement data can also be started centrally from visTABLE®touch in the Material Flow Task Area. For details, see there.

View of the product flows after import

After the import of product flows, initially no thumbnail for the product flow is displayed; instead, a gray field is displayed. Once you click or tap on the field, the thumbnail for the chart can be calculated and displayed after closing the Product Family View.

Overview of the Types of Transport Means

This overview contains the rates for the individual Types of Transport Means.

Cost structure

To normalize the efforts in transportation with reference to the means of transport or for monetary logistics assessment, the rates pertype of means of transport can be specified in visTABLE®logix for the planning period (1 year):

- Investment (fixed) [EUR]: Investment costs referred to the planning period (usually, the rate of depreciation)

- The rates apply for the entirety of means of transport of a type which lie within a area under study of the logistic analysis.

- If the means of transport are depreciated e.g. linearly over a period of 5 years, then specify here depreciation for 1 year as a total of all means of transport of this type.

- If a means of transport is already fully depreciated, it is taken into account in the investment cost rate (fixed) with the value EUR 0.

- If you do not use linear depreciation models, then specify the appropriate value with reference to the planned depreciation period.

- The rates apply for the entirety of means of transport of a type which lie within a area under study of the logistic analysis.

- Investment (variable) [EUR/m]: Costs for the provision of certain types of transport means per meter in the planning period

- This term includes the costs that arise in connection with the provision of the means of transport in the required length.

- Assign here the cost rate incurred per running meter to be erected.

- Transport means which already exist in the production are not taken into account in this cost rate.

- This term includes the costs that arise in connection with the provision of the means of transport in the required length.

- Operating costs [EUR/m] incurred by the means of transport per meter in the planning period:

- This total covers the labor costs for the operator of the transport means, the costs for energy or those arising from wear and maintenance.

- Since the values are normally not available in EUR/meter, they must be calculated from the time-related cost specifications. The costs/time cover the labor costs for the forklift driver and the operating costs for energy consumption (e.g. electricity, diesel).

- This total covers the labor costs for the operator of the transport means, the costs for energy or those arising from wear and maintenance.

Calculation example for the fixed investment costs:

- Planning period: Year

- Depreciation: Linear over 5 years

- Investment costs: EUR 20,000

- Input: EUR 4,000

Calculation example for the variable investment costs of a continuous conveyor:

- Planning period: Year

- Installation costs (without depreciation): EUR 10,000

- Installed length: 100 m

- Input: 100 €/m

Calculation example for the operating costs of a manned transport means:

- Labor costs, incl. payroll taxes (K1): 29 €/h

- Operating costs (diesel) (K2): € 6/h

- Maintenance and repair costs (K3): € 2.50/h

- Average speed (v): 9 km/h

- Input: 0.0042 €/m in accordance with the following formula: (K1 + K2 + K3) / v / 1000

Empty trips, etc.

Please note that visTABLE®touch uses these costs only when calculating the costs for the necessary transport. It results from the current layout structure and corresponds at least to the minimum incurring transport costs in accordance with the specified rates. Any empty trips whether due to the means of transport or the control strategies are not taken into account. Empty trips can, however, be taken into account in the rates with a surcharge calculated in accordance with the occurrence structure.

Types of transport means

The following types of transport means are always available:

- Bridge crane: All transports are performed above ground level; it is, however, possible to approach any position in the work area. It is not possible to specify a Transport Network in the layout for the type ‘bridge crane’. Transport-distance-related (variable) investment costs cannot be specified.

- External logistics (truck, railway, etc.): Type of transport means for the modeling of transports to external locations. The transport costs are typically calculated according to the distance traveled. There is only one cost rate for operating costs.

- Hand trucks: Any hand-guided means of transport with similar cost rates which are driven by human force. The operating costs depend primarily on the number of working persons.

- Overhead conveyors: Overhead transport along a fixed track. The investment costs are determined, for example, by the length of the track. They can be specified by way of a separate cost rate.

- Manual transport: Transport of low masses or volumes directly by employees along defined routes. The only cost-pusher is the personnel required to manage the route.

- Roller track: Conveyor systems driven by motor or gravity which are installed similarly to overhead conveyors fixed along defined routes. The cost structure for roller tracks in visTABLE®logix is the same as with overhead conveyors.

- Tugger train system: Usually, a roundabout with fixed stops for loading and unloading. For this type of transport means, a directed transport network is typically used in the layout. The tugger train system is motorized. In view of the large number of possible configurations and variants of tugger train systems, all cost rates are provided and can be used flexibly.

- Miscellaneous: Types of transport means for transports not determined in detail. All cost rates can be used flexibly.

- Forklifts: Motorized industrial truck. The costs structure is determined by the investment per piece and the operating costs.

- Worker (direct): Type of transport means for manual transport; in contrast to that, however, not to be linked with a route. In other words: There is no Transport Network in the layout for this type of transport means. The cost structure is similar to manual transport.

In addition, new types of transport means can be defined, modified and assigned cost rates:

Effects in the layout

New types of transport means are only provided in the layout for which they are defined. visTABLE®touch provides a transport network with the same name for each newly created type of transport means.

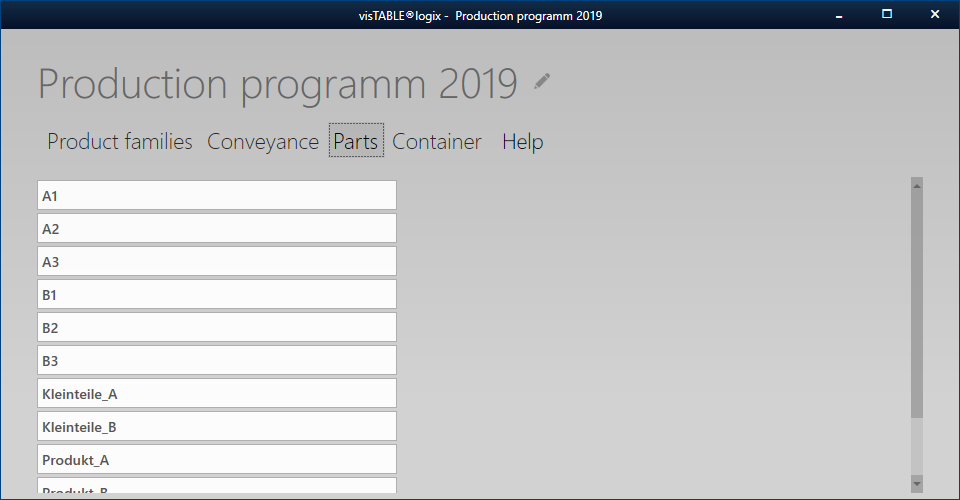

Overview of parts

This overview comprises all part names that were acquired as a part (in the subsidiary flow) when modeling the product flow. In other words: The list only comprises part types which were defined in the Transporteditor with the names of the product families, deviating from the default assignment.

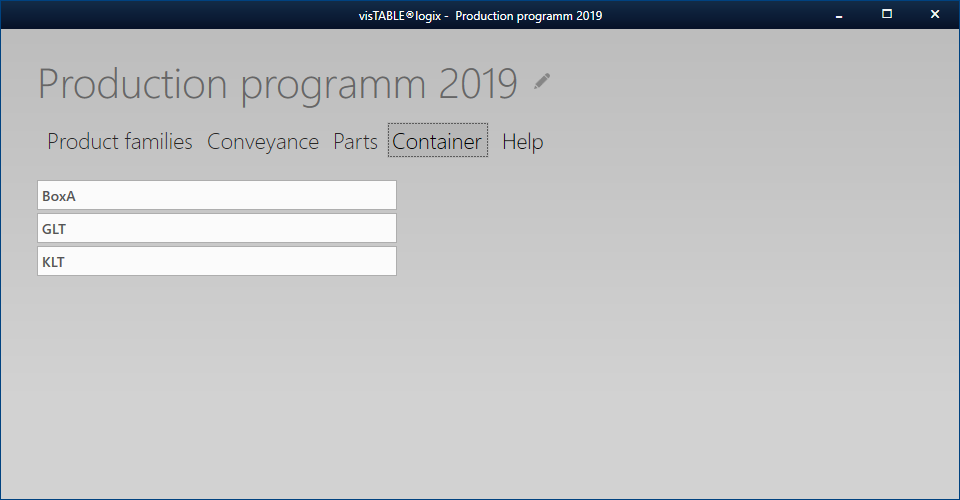

Overview of containers

The list comprises all container names that were acquired as containers in the Transport editor when modeling the product flow.

Procedure when consolidating the container and part overviews

Each entry in the aforementioned lists can be modified as desired. This has influence on the whole production program.

Furthermore, it is possible and necessary to consolidate the part or container list. This will be necessary, for example, if, under the conditions of a Product Flow Analysis at the site, different designations were assigned e.g. inadvertently or for lack of meaningful documents for a type of parts or containers.

- Identify the names in the list which stand for one and the same type of parts or containers.

- Specify a name for this type of parts or containers which corresponds to a name that has already been used in the list.

- Use the key combination

CTRL+Cto copy the name from step (2). - Overwrite all wrong designations in the list which you have found in step (1) with the copied name (to insert the copied correct name, use the shortcut

CTRL+V).

After switching to another view and returning to the Parts or Containers overview, there will only be one single entry for all part or container names identified in step (1). All concerned Product Flows of all product families described in this layout document were refreshed when quitting the overview. In other words: You will not find any wrong designations within the meaning of the definitions.