Basics of visTABLE®touch

visTABLE®touch is the software component for the Structure and Layout Planning of production systems. The focus lies on factory structures for which the Methodical Concept can be used for material flow systems of any complexity. The main objective should, however, always be the common, methodologically founded development and design of layouts to be able to use the advantages from the participatory layout planning.

Intuitive creation of layouts

The work with visTABLE®touch can be compared to the furnishing of a room using physical 2D templates which are simply positioned by moving and rotation in one plane. Any complexity problems relating to the third dimension (height, z coordinate) are deliberately hidden to maintain the flow of the creative design process. Furthermore, this straightforward operating concept allows work with touchscreen devices with the advantage that both manipulation of the layout objects and the calling of software functions required within the framework of the creative flow can be performed with the fingers. Hence, Participatory Layout Workshops can be realized very efficiently, as the working principle can be understood intuitively and immediately by practically everyone. In other words: visTABLE®touch exploits the advantages of a design technique which is very successful in the analog world and makes it accessible to digitization.

Many templates are already included in the standard scope of supply of the software. As representatives of the Layout Objects of the Factory Layout, they are listed in individual catalogs of a library and can be called from the visTABLE®touch User Interface. From there, they are dragged to the grid of the 2D layout area. There is no need to worry about the scale for this process; the correct scale is ensured by the Technical Concept of visTABLE®.

Methodical support in designing the layout

For layout designs to become efficient solutions, the purely creative assembly of layouts using scale models is not sufficient. It is rather necessary to support the Planning Process methodologically. This starts with the specification of the Layout Area and ends with the evaluation of layout variants by way of relevant KPIs. There are the following design approaches, e.g.:

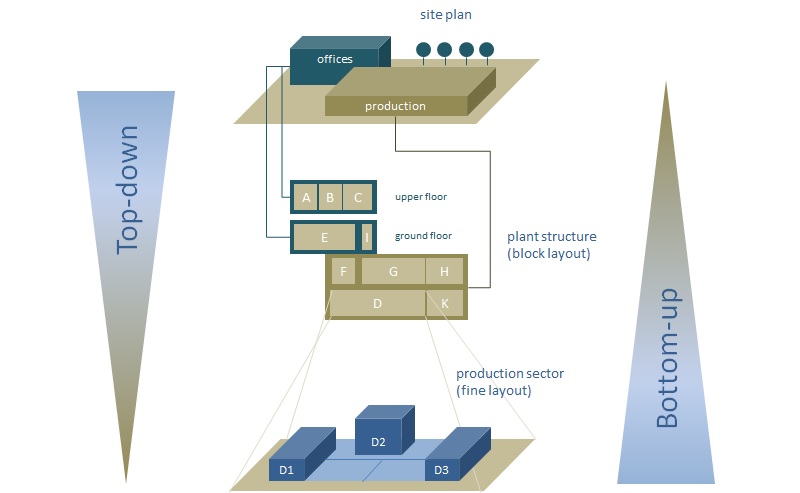

- Top-down (from rough to fine);

- Bottom-up or line-back (from the core of value creation to the peripheral)

These two approaches can be used both for new and re-planning scenarios (so-called greenfield and brownfield engineering), i.e. the methodical focus is placed on design and improvement. The function of visTABLE®touch is here to act as as the Central Software Component; all relevant tasks can be initiated from here, and the results can be stored in a Layout Document.

Sample scenario: Top-down design

The following sketches show 8 typical subtasks of a top-down design process (from rough to fine) for a factory layout; the functions of visTABLE®touch used for the design and the methodical backgrounds are linked.

- Specifying the Layout Area:

- In the greenfield, the layout area is deemed unlimited; a rough frame can be fixed in 2D by setting the layout dimensions.

- In the brownfield, the layout area is usually created by way of the buildings whose groundplans can be integrated into the work area of visTABLE®touch by importing CAD background objects.

- In the greenfield, the layout area is deemed unlimited; a rough frame can be fixed in 2D by setting the layout dimensions.

- Integration of the Dimensioning Results:

The dimensioning is typically performed in one arithmetical operation in the form of table calculations. The results are tables with the resource groups as blocks (e.g. mechanical manufacturing: 350 m², incoming goods department: 180 m²). The blocks are created semi-automatically as Layout Objects in the Layout Area of visTABLE®touch with preliminary specified dimensions by importing the block layout information by way of Excel®. - Analysis of the Material Flows:

- Known logistical dependencies can be accepted in the formats used in this field (e.g. flow table) and with the appropriate Intensity Measures (e.g. as a mass flow) from Excel® templates directly in visTABLE®touch.

- If any flow information is missing, it is gathered by way of analyses of the (logistic) processes in accordance with the principle of value stream mapping. To this end, start the visTABLE®logix app directly from the visTABLE®touch User Interface.

- Known logistical dependencies can be accepted in the formats used in this field (e.g. flow table) and with the appropriate Intensity Measures (e.g. as a mass flow) from Excel® templates directly in visTABLE®touch.

- Optimizing the layout:

The structuring techniques implemented in visTABLE®touch can be used to interactively optimize network and line structures by moving the layout objects in a participative way of working. visTABLE®touch supports you here illustratively by Visualization of the Flows, of the layout priorities and evaluation of the resulting Efforts in Transportation. - Designing transport routes:

- The routes for certain Types of Transport Means through the layout can be specified by way of Transport Networks.

- The number of transports required per route section is reflected in the Network Load which serves as an input from the relevant guidelines for calculating the widths for roads.

- The routes for certain Types of Transport Means through the layout can be specified by way of Transport Networks.

- KPI-based Logistics Assessment:

The efforts in transportation are calculated and compared to each other for each type of transport means by way of appropriate diagrams. Thus, it is possible to evaluate optimization ideas regarding the logical concept immediately. - Segmentation for distributed detailed planning:

The layout areas that are to be planned in detail by planning teams are to be extracted from the overall layout by forming modules. To allow distributed working, the modules are to be stored in the Shared Library. - Merging detailed planning results in the master layout:

- The released variants are stored by the planning teams as (merged) modules in the designated folder of the Shared Library.

- The Replace function is used to automatically replace the areas of planning which were identified during the segmentation with the modules correspondingly planned in detail.

- The released variants are stored by the planning teams as (merged) modules in the designated folder of the Shared Library.